The second project for my advanced manufacturing and design course was focused on learning how to use the CNC mill that we have in our shop. We were told to design a piece that would make use of a variety of tools with a complicated shape. I took my inspiration from my love of Chipotle …

The goal of this project was to explore the capabilities of additive manufacturing using an FDM 3D printer. We were told to create an object that would be unmanufacturable using conventional techniques. I decided to create a Klein bottle, a mathematical object similar to a Möbius strip except that it has no boundary. I designed the …

The Volcano, as my team of 3 calls it, is a self automated music machine that was created during the course MEAM 511, introduction to creative thinking course. It was a project that demanded a machine be entirely mechanical and able to play music for 45 seconds. I designed the ball release mechanism which is …

The task of this project was to generate electricity using only wind power and no rotating parts. My team built an apparatus that could hold a tensioned rubber belt which would exhibit the phenomenon of aeroelastic flutter at just 13 miles per hour. The belt would begin to vibrate and by attaching magnets inside copper …

These pieces were created during the winter of my junior year. I spent 4 hours at a glass blowing studio in Boston and during that time created these two paperweights. Each one is the size of a fist and weighs close to 1 kilogram. The coloring inside is colored glass that was gathered over the …

I designed and fabricated an apparatus for launching a custom built carbon fiber and aluminum rocket body for use with the sophomore lab course. The rocket and launcher was built to withstand over 160 PSI giving it the thrust to fly upwards of 25 meters. The base unit is made of 60 series aluminum and …

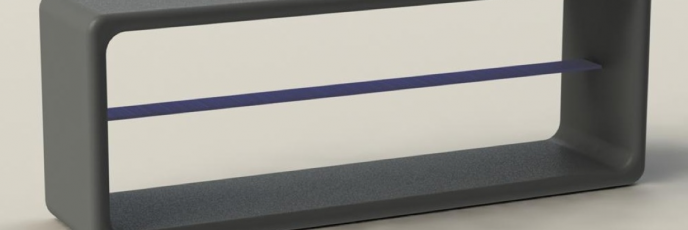

This is a materials sample holder that I created during the summer between my sophomore and junior year. I was granted the Jacob M Abel internship to work on redesigning the curriculum for MEAM 247, the required lab course for Sophomore engineering students. I personally tested all the samples using an Instron machine to test for …

I manufactured and assembled this engine in a introductory machining class, it is a closed cycle Gamma type Stirling engine that works based on heat differential. I have tried to highlight not only the aesthetic qualities of the engines design but also the sections that I had liberty to design; the main designed components are …

Both the Horseshoe and Ghandi were created my sophomore year for the course FNAR 264, digital design foundations. I drew the pieces and then scanned in the images so I could trace over them in the program and create the vector images. They are 8.5 x 11 and were created using Adobe Illustrator.

AccuPark is a concept for an urban parking system wherein all payments are done via mobile phone and parking can be found using GPS units of smart phones. I developed the design with Evan Dvorak and Harry Green during an introductory design course in my freshman year at the UPenn.